Wood Veneer to make Furniture

The uses of wood veneer in the furniture industry is very common. The price of wood is going to be more and more expensive. The wood with beautiful grain such as: teak, cherry, mahogany, walnut, rosewood, etc. are not only expensive but also become difficult to be outsourced. Many peoples are talking about keeping the wood and forest to save the earth. Moreover the global warming issues are very strong recently and influence many aspect in human life. This condition has made strong pressure to the furniture industries. The woodworking industry have to do action to save the wood as its main raw material. Since that, more furniture factories prefer to use the wood veneer to make panels, board replacing the solid wood.

The veneer technology actually is not a new technology, it was already known and developed since the end of 19 century. And now the veneer technology is already very advanced to meet the need of woodworking industries. Veneer is wood log that is sliced in to form very thin sheet layer, The common thickness is usually between 0.2 mm to 1 mm. The other thickness are also available but must be special ordered. Wood veneer is usually made of from premium wood that has beautiful grain, but most of commercial wood now are also available in the veneer form. Veneer is the solution to make the wood panels with special grain and looked such as: crotch, burl, swirl, etc. but in the low price The veneer has some advantages compared with wood; his price is considered cheaper, the flexibility in arrangement and also the better stability.

The veneer technology actually is not a new technology, it was already known and developed since the end of 19 century. And now the veneer technology is already very advanced to meet the need of woodworking industries. Veneer is wood log that is sliced in to form very thin sheet layer, The common thickness is usually between 0.2 mm to 1 mm. The other thickness are also available but must be special ordered. Wood veneer is usually made of from premium wood that has beautiful grain, but most of commercial wood now are also available in the veneer form. Veneer is the solution to make the wood panels with special grain and looked such as: crotch, burl, swirl, etc. but in the low price The veneer has some advantages compared with wood; his price is considered cheaper, the flexibility in arrangement and also the better stability.

How wood is sliced to make veneer?

The wood can be sliced in some different way and it will determined the veneer looked. There 5 ways of cutting veneer that commonly used. They are: rotary slicing, flat slicing, quarter slicing, half round slicing and rift cut slicing.

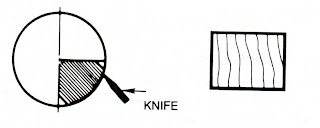

Rotary slicing

Timber is mounted in a certain position and then be rotated so that the blade is driven to cut wood from the outside wood like unrolling paper. This is the most economical cutting method because it can produce wide sheets of wood.

Timber is mounted on a certain position, then be moved to so that the knife cut parallel to the mid line of wood. This method is producing the appearance of a “cathedral effect”.

Quarter slicing

Timber is mounted on certain positions and then move the knife to cut at an certain angle. This cutting method produce the strip grain pattern. These stripes pattern can varies depend on the wood.

Half round slicing

Variation of the rotary where timber is fitted with a certain distance from the center of the circle rotation A half, third or quarter of a log is attached to a plate on a lathe and turned. Half-round slicing is used to accentuate the different grain in certain woods.

Rift cut slicing

More variation of the rotary slicing, timber is mounted on a certain position, then wood is cut into a quarter and moved around to the knife. Rift slicing also achieves a straight grain pattern, but avoids the appearance of “flake” that occurs in some species when quarter sliced.

Veneer is attached to the core panel to make board panel. The common core for veneer are : m.d.f., particle board, or laminated wood from the wood with cheap price. Sengon wood, or jabon wood are the "cheap" wood that can be used as veneer core. M.d.f. (medium density fiberboard) is processed wood material made from wood pieces cooked in a tank (digester), and then this pulp is passed through a roller to form a board with a certain thickness and sizes. The particle board are pieces of wood that was ground and then mixed with glue and pressed to produce board sheets with a certain thickness and sizes.

The veneers can be arranged to form a certain pattern and produce a more attractive appearance. With many different slicing techniques, veneer is be able to produce many patterns to varied wood looked. This veneer can be more flexible and can be arranged with more varies by optimizing the patterns of slicing and the type of veneer. With a good lamination, the veneer is also more stable than a solid wood board. Wood board has more pores than veneer on m.d.f.; so it has higher risk to the wood movement caused by the changes of temperature and moisture content. Veneer can also solve problems at the difficulties to get a long and wide wood.

With his advantages, the veneer is preferred as material to make furniture, especially to make wide, long panels. The furniture industry has replaced the use of wood panels to veneer panels in the manufacture of boards, especially for indoor furniture. For outdoor furniture, the veneer usage is still limited because its not strong enough to withstand the outside weather. The veneered panel for exterior must be made with special glue and special core which could be more expensive than the solid wood.

Post a Comment for "Wood Veneer to make Furniture"